Environmental Factors >

Sustainable Procurement and Supplier Management

Sustainable Procurement and Supplier Management

Sustainable Procurement

To deeply entrench the concept of sustainability in our procurement practice and to work with suppliers to take advantage of the opportunity to create more value together, FFHC has introduced the "ISO 20400:2017 Sustainable Procurement-Guidance" since 2020, in addition to implementing the seven core themes in our procurement practice. In 2024, we continued to complete the "Performance Assessment for ISO 20400 Sustainable Procurement-Guidance", and received an SGS certificate as well as a highly acclaimed Level 4 rating. The green procurement target for 2024 was NT$84.41 million, and the actual procurement amount was NT$101.514 million. We have been verified as a benchmark organization for "green procurement by private enterprises and organizations" by the Taipei City Government for 10 consecutive years. We also delivered on our green procurement commitment to the Coalition of Movers and Shakers on Sustainable Finance.

Process for Introducing the ISO 20400 : 2017 Sustainable Procurement Guidance

Supplier Sustainability Management

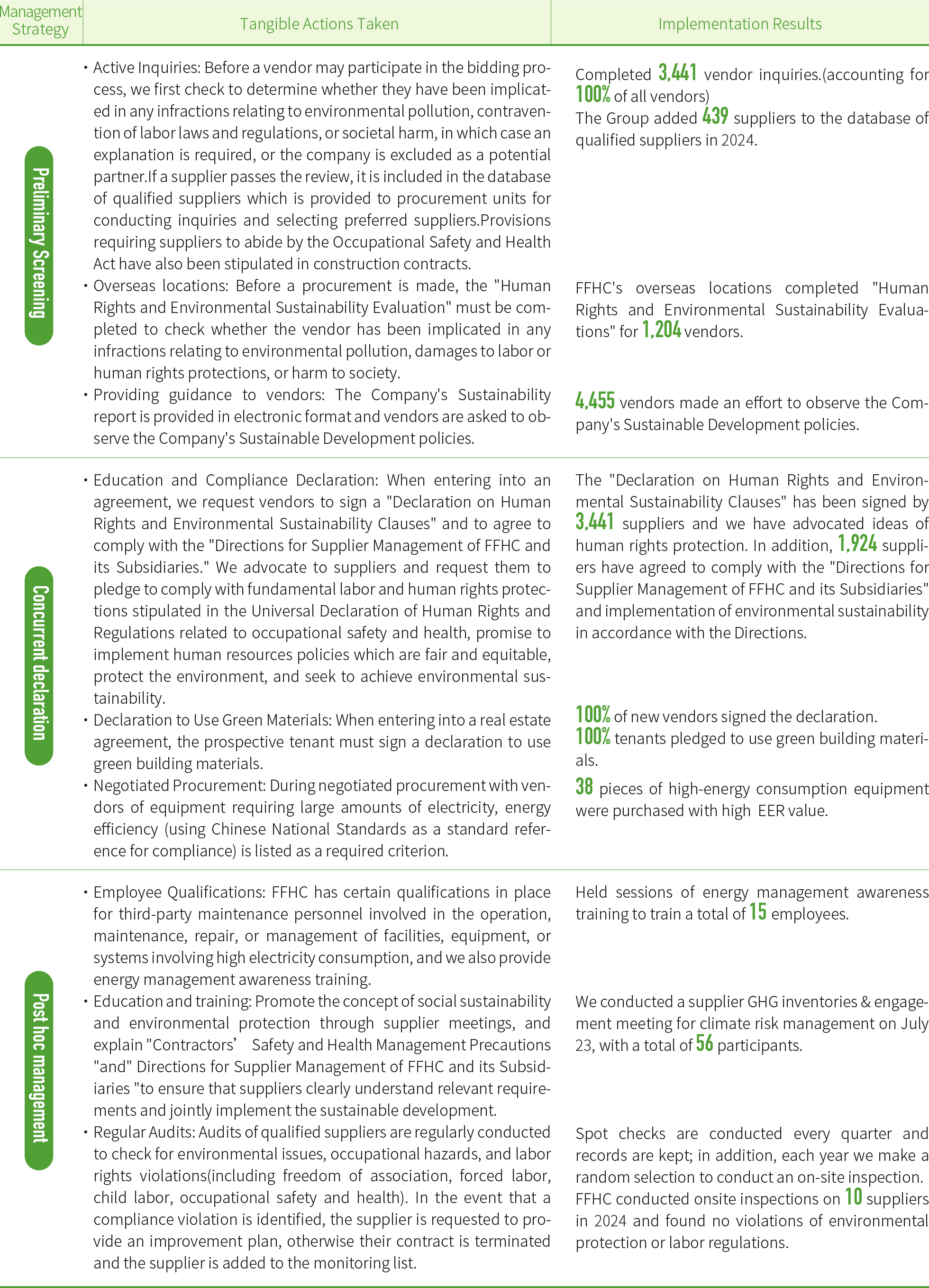

FFHC established the "Supplier Management Guidelines" as the policy and guiding principles for the management of suppliers of the Group. We require suppliers to comply with the Guidelines when signing contracts and we require suppliers to sign the "Human Rights and Environmental Sustainability Clauses" and to increase awareness. We also require subsidiaries to use site visits and audits to encourage suppliers to implement the Guidelines. The contents include basic labor rights for suppliers, environmental protection, sustainable management, and occupational safety and health regulations.

When formulating our procurement and tendering guidelines, FFHC valued fairness and openness throughout the procurement process, and has established three steps for supply chain management. Through supplier management, we have sieved out qualified vendors who are aligned with the spirit of sustainable development as our long-term partners in 29 categories, including: purchasing and maintenance of energy-saving & IT equipment, construction and furnishing engineering, business-related OA equipment, landscaping, and environmental greening. As a principle, the main procurement regions include suppliers from the country in which our operations are based and those close to our business locations. In 2024, 100%*1of all purchases came from local*2 suppliers to ensure the stability and localization of the supply chain, as we reduced carbon emissions in the transportation process while creating local employment opportunities.

To realize an environmentally responsible business model and to actively build up green supply chains, FFHC has strengthened our supplier ESG risk management since 2022. ESG risk factors have been added to our audit items, and we also conduct investigations into suppliers from whom we spend large sums of money purchasing goods. In July 2024, we conducted supplier GHG inventories and engagement meetings for climate risk management, as we guided suppliers to gradually complete their carbon inventories. A total of 120 IT equipment, maintenance, printing and publicity vendors with more than NT$1 million in procurement amount as well as business dealings with the Company within the previous two years were chosen to complete their filing of carbon inventory data on the "Supplier GHG Inventory Platform", which serves as the basis for grading. Vendors graded A or B are entitled to performance bond discounts when they take part in procurement tendering cases in 2025, as part of our efforts to encourage our suppliers to adopt low carbon management measures.

To realize an environmentally responsible business model and to actively build up green supply chains, FFHC has strengthened our supplier ESG risk management since 2022. ESG risk factors have been added to our audit items, and we also conduct investigations into suppliers from whom we spend large sums of money purchasing goods. In July 2024, we conducted supplier GHG inventories and engagement meetings for climate risk management, as we guided suppliers to gradually complete their carbon inventories. A total of 120 IT equipment, maintenance, printing and publicity vendors with more than NT$1 million in procurement amount as well as business dealings with the Company within the previous two years were chosen to complete their filing of carbon inventory data on the "Supplier GHG Inventory Platform", which serves as the basis for grading. Vendors graded A or B are entitled to performance bond discounts when they take part in procurement tendering cases in 2025, as part of our efforts to encourage our suppliers to adopt low carbon management measures.

*1:Calculation was done based on the database list of qualified suppliers in 2024.

*2:Local refers to countries in which various locations of operations are based.

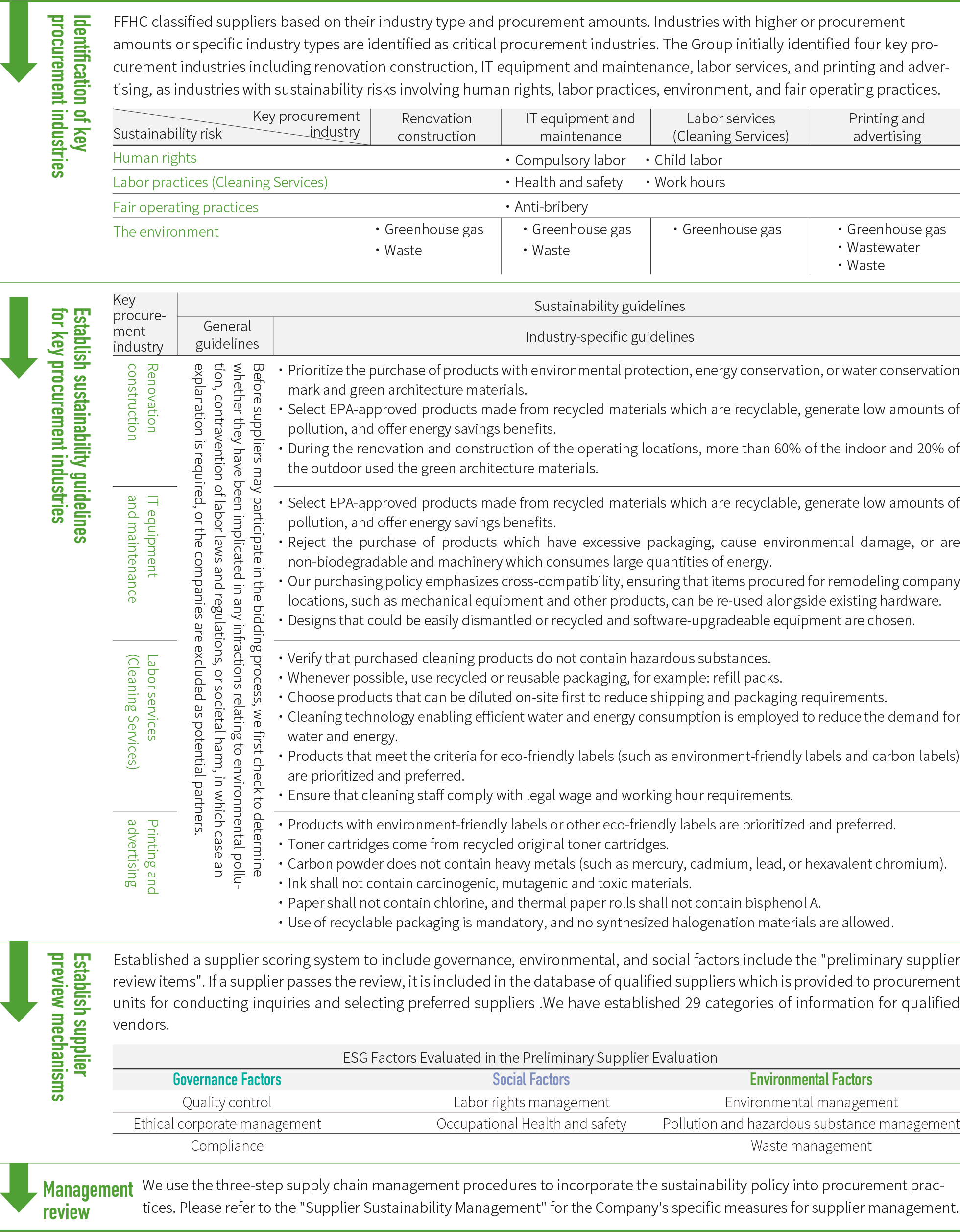

◎ 3-step Supply Chain Management Process

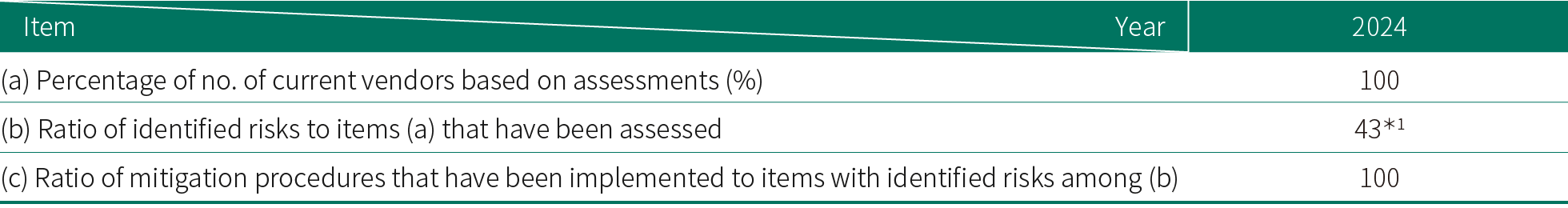

◎ Assessed whether suppliers have violated issues related to human rights and percentage of mitigation measures that

have been implemented.

*1:We compiled statistics using the number of suppliers in 2024. Among 507 suppliers, we identified 220 suppliers with human rights violation risks, including 5 suppliers in the clothing category prone to occupational hazards such as muscle and bone injuries, 3 suppliers in the moving company category, 100 suppliers in the renovation category, 25 suppliers in the air conditioning category, 59 suppliers in the plumbing engineering category, 18 suppliers in the fire protection engineering category, 6 suppliers in the landscape engineering category, and 4 suppliers in the solar power generation engineering category.

*2:There were no cases where suppliers of the Company received penalties for violation of labor laws before signing contracts or within the contract duration and failed to make improvements. Therefore, there were no records of termination of partnerships with suppliers.

◎ Identification of key suppliers' potential environmental and social impacts and their improvement rates

・Prior to tender opening in 2024, the Company had evaluated 211 key suppliers (with over NT$1 million in procurement) with respect to

their potential environmental and social impacts.

・We looked into the suppliers that had been identified as having materially substantial or potentially negative impact on environment and society. We found that none of them had violated regulations pertaining to environmental protection, labor protection, or occupational safety and health.

・After our evaluation and investigation, the above-mentioned suppliers were not involved in any regulatory violations in 2024. Therefore,

no contracts were terminated.